..................................................................................................................................................................................................................................................

Sensors - Instruments - Controls

Bar Code Verification Systems

Verify that printed barcodes on unit dose packages are readable and correct

Applications:

Inspecting, monitoring and reporting in unit dose post-printing and packaging applications

Benefits:

Quickly identifying incorrect stock or illegible bar codes and stop production, notify an operator, or divert bad product. Verify the correct number of packets in a unit dose strip.

Target Barcode Inspection for Unit Dose Pharmaceutical Packaging

Verifies Item Barcode and Packet Count, Accumlates Batch Counts

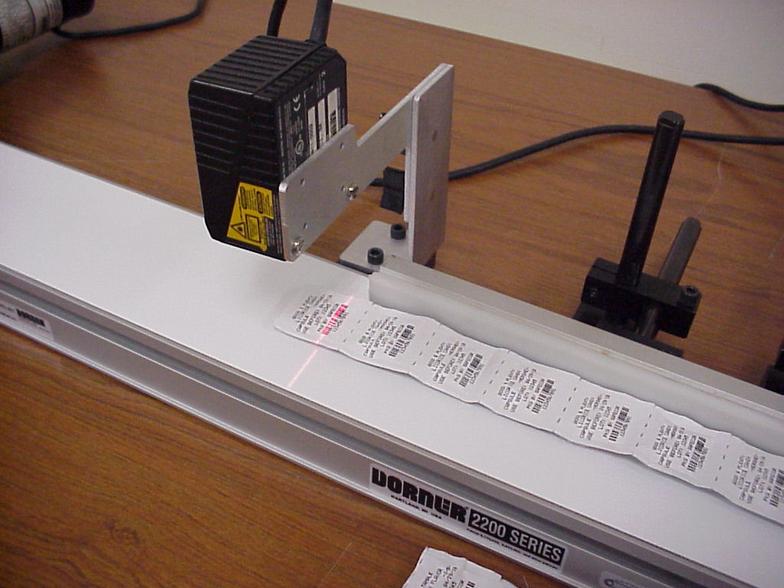

The new Target Barcode Inspection System for unit dose pharmaceutical packaging automatically inspects unit dose strips to insure that barcodes are printed on packages, readable and correct. The system also insures that unit dose strips contain the correct number of dose packets. The Target System is designed to complement table-top unit dose packaging machines, aiding packagers in achieving bar code medication administration (BCMA) quality objectives.

The system controls a motorized conveyor, automatically delivering packages through an inspection station, generating audible signals for pass or fail. On detecting an error, the system stops the conveyor for operator intervention. The Target System also maintains and displays an active batch count of the number of doses inspected. Inspection setup and results can be exchanged with a PC using the system's network interface.

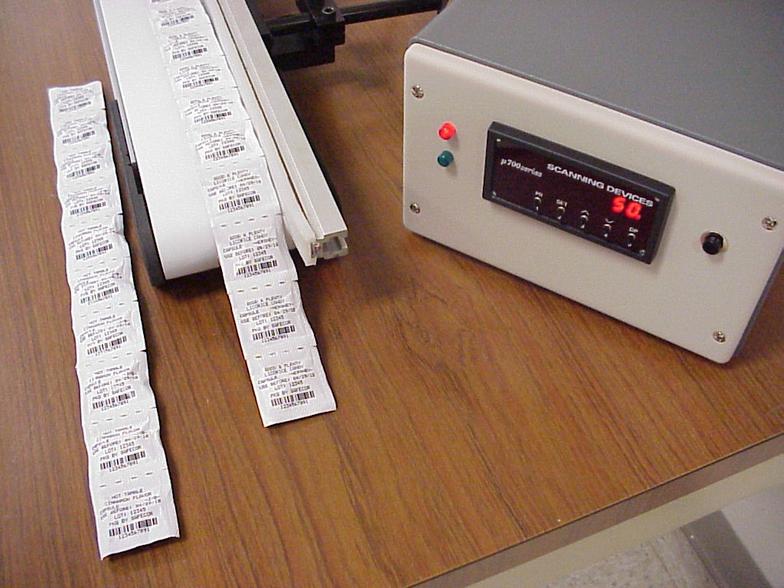

Compact Table-top Barcode Inspection System for Unit Dose Pharmaceuticals

The system controller has a six-digit numeric display to show the accumulating batch count and a two-digit display to show the number of doses within the current strip. It also has an audible signal that can indicate inspection success or failure, Red and Green indicator lights, a start/stop button and five keys used for setup. The controller has connectors for barcode scanner, motor drive and RS232 PC interface. The RS232 interface may be used to transfer inspection parameters and results between PC and system controller. Alternately, inspection setup can be done with front panel keys, allowing the system to operate independent of PC.