..................................................................................................................................................................................................................................................

Sensors - Instruments - Controls

Label Counting Options

Scanning Devices offers a full

range of options for your next

Label Counting Table.

We will work with you to determine

your needs and custom

configure a Label Table with

just the options you are looking for.

Label Table Options:

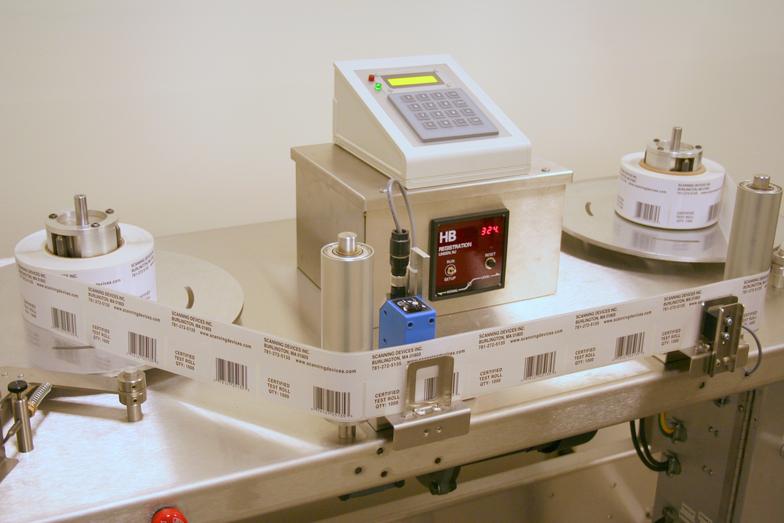

Bi-Directional Label Counting:

Dual motors installed on your Label Counting Table

allow you to count a roll of labels and then rewind the

roll by just selecting a singe switch. Or, you can count

labels in the forward direction and then count again

during the rewind process.

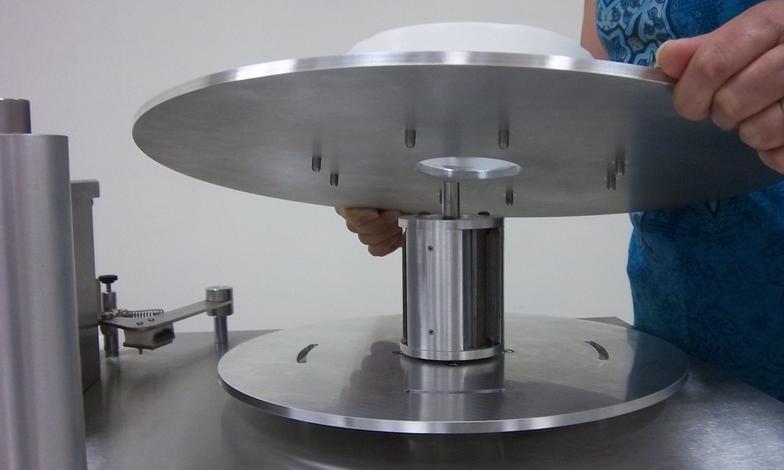

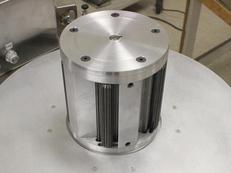

18" Lift-Off Disks:

Our standard machine comes with

13" diameter label disks, but if you count larger or

heavier rolls, or just want a simple way to remove

labels once they are counted you will want to add this

option. This option allows you to count label rolls up

to 18" in diameter and once counted you simply lift

off the disks to remove the labels from the table.

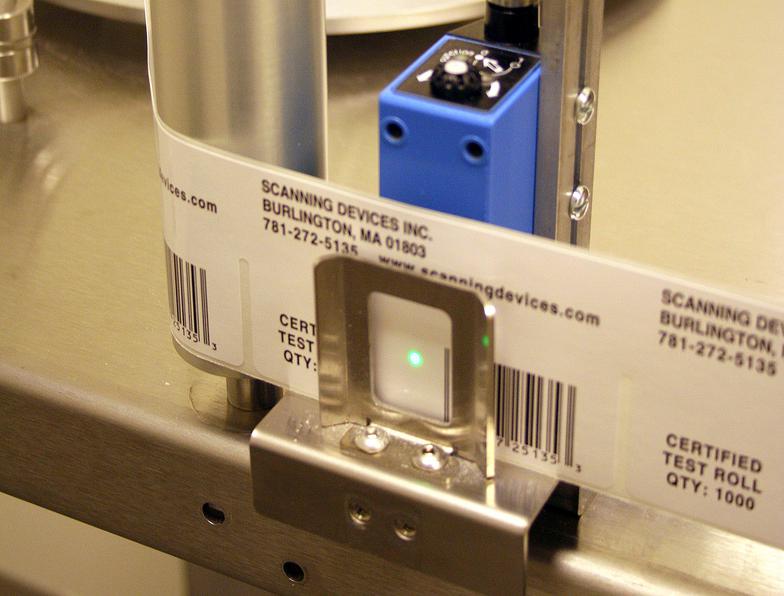

Clear Label Counting:

Specialized sensors are added to your machine

which allow you to count clear labels on a paper

web or clear labels on a clear web with accuracy

and at high speed. Brackets allow for easy height

adjustments for different sized clear labels

Missing Label Detection:

During a counting operation this option will detect when

a label is missing from the roll. The machine will

find the missing label and either report it to the

operator, or, using an electronic brake, stop and back

up to the spot of the missing label so it can be marked

or replaced. (Requires Constant Speed Option &

Electronic Brake). When a missing label is detected,

the count remains correct.

Splice Detection:

This option automatically detects the presence of a

splice in the web by detecting the colored tape used

to mend that splice. This feature stops

the web during counting so you can inspect the

splice, mark its location, or reject the roll. An accurate

count is maintained in this process. (requires electronic

brake).

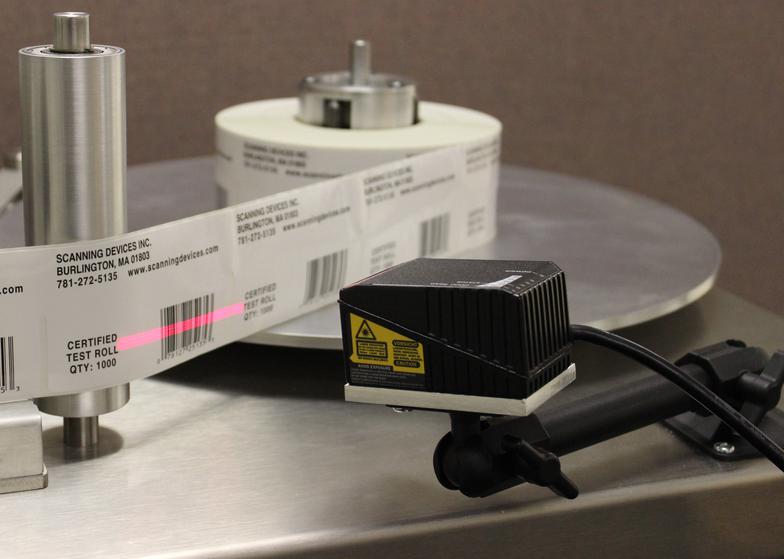

Barcode Inspection & Verification:

Validate that the barcodes on your label rolls

match what you expect (are correct), are readable

and present. Stops the web during the counting/

inspection process so that the bad barcode can

be viewed by the operator and an action taken.

Label rolls can be counted and barcodes inspected

simultaneously.

Electronic Brake:

Many of our customers are not just counting labels

but are looking for errors like missing labels,

bad or incorrect bar codes, or unwanted splices.

Adding an Electronic Brake to your table allows

for a quick stop to inspect or correct these types

of errors.

Preset Label Count & Count Adjust Option:

This option allows the operator to enter the number

of labels that need to be counted/seperated from

a larger roll. Once the preset number of labels is

counted the label table will stop the web so the

labels can be removed. This option also

allows an operator to add a specific number of labels

to the count. (Used when label rolls have no or

insufficient web leader.)

Constant Speed Option:

This feature keeps the speed of the web at a

constant speed. This is important for bar code

inspection, missing label detection, and is beneficial

when counting larger rolls. Motor speed is

automatically adjusted as the size of the take-up

reel changes.

6", 3", or 1" Core Chucks:

Our Label Counting Tables come standard with

3" mechanical core chucks, they provide a secure

grip on the label roll without the need for compressed

air at the site. Special sized cores are available

including 6" and 1" mechanical core chucks.

Record Keeping & Validation Software:

Two software packages are available for use with your Label Counting Table.

- The first allows you to document each counting operation by recording the date/time, job name, operator name, product description, final count and the direction of count. RS232 connection allows for automatic transfer of label count and count direction eliminating recording errors.

- A second software package provides a structured and documented process for validating your Label Counting Table. Computer commands control critical steps in the process eliminating human error. Validation data is transferred via the direct RS232 connection to the computer.

- Count and Validation data can be saved and exported to Excel or other database programs for record keeping.

Visual Inspection Strope Light:

Strobe light is installed on the machine and directed at the moving web. Provides a vehicle for visual identification of labels being processed.

5" Locking Casters:

Locking casters allow for easy relocation

of the Label Table within your facility

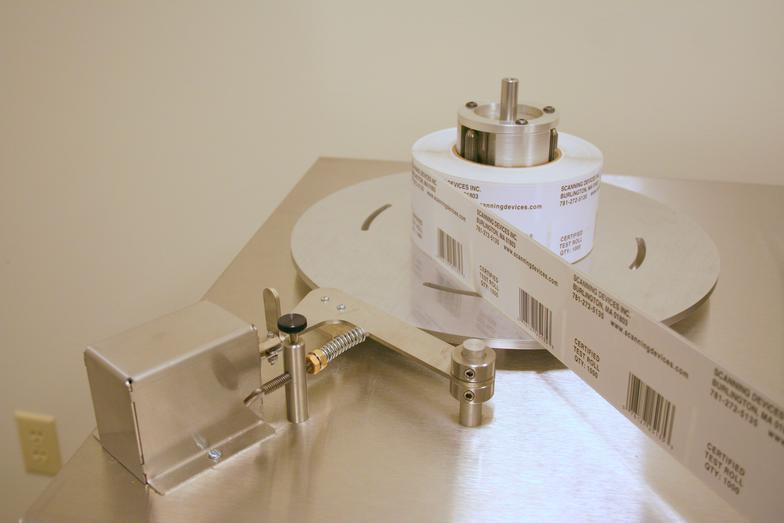

Certified Test Roll:

Tamper evident roll of 1000 labels certified at the factory

for accuracy. Perfect for validating your Label Table,

training, testing, or demonstrations.

Other Options:

If you need a feature that is not described here, just ask. Over the last 15+ years of building these machines we have probably built what you are looking for, for another customer.