..................................................................................................................................................................................................................................................

Sensors - Instruments - Controls

HB Quarter-DIN II

Bi-directional - Registration Control

Applications:

Automatic Label Application

Benefits:

Automatic Registration Correction

Out of Registration Alarm

Reduces Scrap – Improves Quality!

The Quarter DIN II is a bi-directional registration control system with out-of-registration alarm and outputs for automatic correction. It is particularly well suited to automatic label application, insuring label position and preventing label feed if registration is not maintained.

The system consists of three components:

1. Registration Mark Scanner: Locates the label reference.

Three HB scanners are available to cover a broad application range:

- CX6A - general-purpose mark scanner for most scanning situations.

- CX7 - special purpose color contrast scanner for low contrast labels.

- CX8 - fiber optic scanner for small marks or hard to reach places.

2. Selector Switch: Rotates with label feed to segment the label repeat into four regions:

- In Registration, no correction required

- Forward mark, reverse correction required

- Reverse mark, forward correction required

- Out-of-registration, situation required intervention

3. Quarter-Din Controller: Receives input from scanner and selector switch, determines registration state and generates correction output. The controller determines the relative position of the registration mark. If not in-register, the controller generates a forward or reverse correction. The time duration of corrections is set by two independent front-panel adjustments. A manual jog switch adds to the control capability. As the name implies, the Controller is panel-mounted in a 1/4 DIN standard cutout.

Correction outputs are NPN transistors suitable to drive relays or solid-state switches for controlling correction motors. When a correction is required, the forward or reverse output energized for a time set by the front panel dials. Forward and Reverse times are independent to allow compensation for drift or stretch.

Out-of-Registration control can be selected from the front panel. If selected, the controller energizes the out-of-registration output if five connective labels are determined to be outside the registration band. The out-of-registration output may be used to sound an alarm or to interrupt label feed to prevent scrap production.

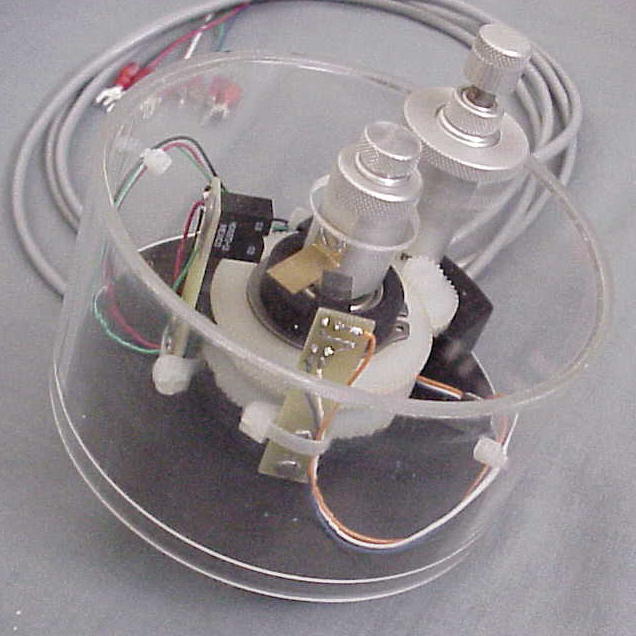

The selector switch consists of two optical slot scanners with a rotating flag. The switch is coupled so that the flag rotates once per label repeat. The interupters are mechanically positioned to define the four regions as the flag rotates. The selector switch is enclosed in a transparent plastic housing with mechanical adjustment accessible from the front. The transparent housing allows visual inspection during setup.